LP 26/2021 Safety Reminders: Carriage of Containers on Bulk Carrier

The excessive demand over a certain type of sea transportation may affect demand over alternative ship types so that an overall supply-demand balance could be reached. At present, the soaring container shipping market has affected the operation of traditional bulk carriers, some of which are even chartered for the carriage of containers. This requires a lot of technical planning as carriage of containers on bulk carriers would inevitably lead to a number of issues in the ship’s strength, stability and watertightness, no matter the containers are loaded on deck and/or inside cargo holds.

I. Technical considerations

The SOLAS Convention has defined “bulk carrier” in Chapter IX as a ship that is “constructed generally with single deck, top-side tanks and hopper side tanks in cargo spaces, and is intended primarily to carry dry cargo in bulk, and includes such types as ore carriers and combination carriers”. The regulation has taken into account the maximum utilisation of cargo holds spaces during the design and construction of bulk carriers by allowing different arrangements for either bulk cargoes or baled cargoes.

In terms of whether containers can be loaded on bulk carriers, the answer is yes as they can be stowed in cargo holds by measuring bale capacity or on deck by ensuring hatch cover strength and sealing, as long as requirements can be satisfied on ship stability, structure and safe watchkeeping.

Usually, there will be broken stowage when containers are loaded in the cargo holds of bulk carriers, and the vessel is often full in terms of capacity but not down in terms of weight, considering the limited strength of bottom plates and the impact on stability. Compliance with the load line convention can also be satisfied even with additional containers stowed on deck.

Cargo holds structure of a Panamax Bulk Carrier

II. Operational considerations

- Ship’s stability

The ship’s stability when carrying bulk cargoes depends primarily on the nature of the cargo, the stowage factor and the container stack height. Since broken stowage will be inevitable considering the shape of containers and the room provided for safe access, the volume centre of the stow can be roughly taken as the centre of gravity when determining the transverse stability of the ship, provided that heavy units are evenly distributed in bottom tiers and light units on top, or the stability should be calculated based on the weighted average of each container’s centre of gravity.

Bulk carriers generally have sufficient stability as they are designed with a rather high block coefficient and a low superstructure. Stability is not necessarily the major concern when containers are stowed in cargo holds, except that an excess of stability may give rise to stricter requirements on cargo securing and lashing, and when the containers are stowed on deck or hatch covers, the stability criteria may be affected due to increased heeling moments.

Pursuant to the freeboard computation in the Load Lines Convention, type A ships are designed to carry liquid cargoes and have small access openings with high watertightness and high degree of safety against flooding. Bulk carriers, which do not come within the provisions of type A ships, shall be assigned with freeboards of type B ships. Such ships which comply with the requirements of the convention can be assigned a reduced freeboard and increased cargo capacity, provided that the value shall not be reduced by more than 60% of the difference between the type B and type A values for the appropriate ship lengths. The B-60 type ship, when loaded to its summer load waterline, should remain afloat in a satisfactory condition of equilibrium after flooding of any single damaged compartment at an assumed permeability of 0.95 (excluding the machinery space). Therefore, the permeability of cargo spaces and conditions of loading should be examined to ensure adequate buoyancy in the case of hull damage.

- Hull strength

The containers loaded either on or under deck may affect its strength in contact with the bottom plate. The main weight bearing components of a container are the four corner posts, and therefore the total weight of the cargoes is not evenly distributed over the bottom plate, but on the contact points with the corner posts. A strong pressure is then generated locally.

Locking and stacking devices are placed on containerships to render sufficient support to stowed containers so that steel plates would not be deformed. While the containers are not rested on stacking devices when stowed on bulk carriers, the IMO has recommended in the CSS Code that bottom-tier containers should be stowed on timber of sufficient thickness to transfer the load evenly on to the structure of the stowage area.

Where bulk cargoes and containers are both loaded in the cargo holds, the cargoes should be arranged in a way to withstand the longitudinal forces and prevent exceeded shear forces and bending moments.

Containers stowed in the cargo holds could cause damage to the bulkheads or frames if they were to move and should therefore be secured by suitable lashings and gaskets. For containers stowed on the hatch cover, the hatch cover strength should be first checked, or structural deformation may seriously impact the vessel’s watertightness.

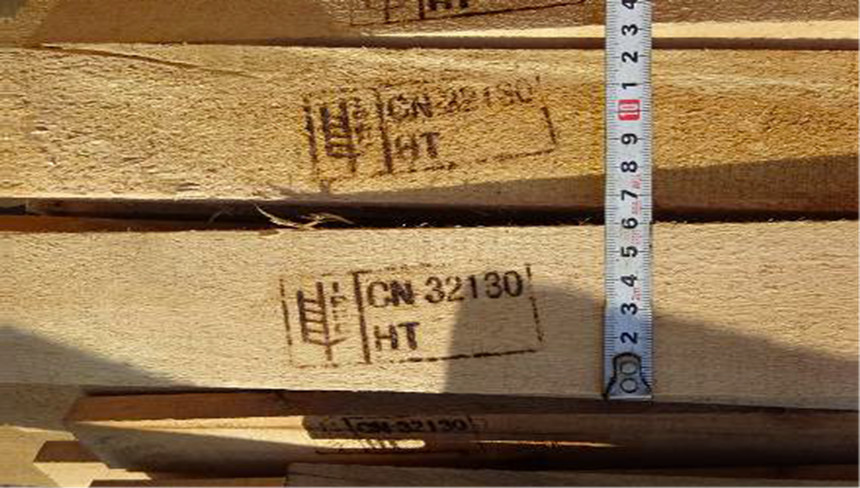

P&I surveyor measuring the timber shoring

- Cargo securing

Unlike containerships and multi-purpose ships, dry bulk carriers are not equipped with sufficient locking devices or lashing gears, which makes it extra important to adequately secure the containers to the ship through scientific and effective methods. Welded attachments should be aligned to decks and bulkheads with stiffeners, away from the oil tank and with consideration of the strength of the bottom plates, frames, bulkheads and hatch covers.

Some special locking devices are indispensable in satisfying cargo securing requirements and welded angle iron may be necessary against sliding and tipping, or the violent rolling of the ship during the voyage will cause transverse and longitudinal sliding, and further collapse of containers and damage to the hull and the cargoes inside.

Containers loaded int the cargo hold with general cargoes

- Watchkeeping

The height of the container stack above the deck or hatch top of bulk carriers is limited. This is because bulk carriers are not designed to load cargoes on the deck and the accommodation spaces are not positioned as high as that on a containership. The field of vision from the conning position, the main steering position and each bridge wing shall under all conditions of draught, trim and deck cargo conforms to the requirements as provided in regulation 22 of Chapter V of the SOLAS Convention.

- Safe access

According to the requirements of the Cargo Securing Manual, safe access should be provided on containerships and on other ships specifically designed and fitted for the purpose of carrying containers on deck. Where containers are loaded on the deck or hatch cover of bulk carriers, safe access and safe places of work should be maintained for persons engaged in cargo securing operations. Convenience should be provided for the crew members to carry out routinary work, access ullage openings and examine or use any firefighting, lifesaving and oil spill facilities without obstructions.

- Crew

Masters and crews traditionally work on dry bulk carriers are not necessarily familiar with the operations of container cargoes. Where the stowage, isolation, lashing and securing of cargoes are not effectively supervised or suitably cared by the master and crew, technical support from the company, the classification society or the terminal will be necessary to instruct the operation on board.

III. Stability and the Cargo Securing Manual

The SOLAS Convention has specifically provided that the master of the ship should be supplied with reliable stability information and the approved Cargo Securing Manual. With calculation during the design or the building stages and approval of the Administration, both will serve as an accurate guidance as to the safety of the ship, the cargo and the personnel.

Further, for bulk carriers to load containers or other cargo transport units, it is necessary to confirm whether a container packing certificate is available or whether the loading condition and securing arrangements are to be verified by an appropriate standard. Where the loading condition is not acceptable or there are no effective securing arrangements included in the Cargo Securing Manual, professional guidance from the classification society should be sought unless alternative measures are taken to satisfy the requirements of the authorities concerned, or the ship may be detained in accordance with the applicable law of the port state.

Lashing rods for containers

IV. Advice to Members

- Prior to loading of containers on bulk carriers, check the Class approved Cargo Securing Manual for detailed plans for stowage arrangements and the manner of securing or any alternatives. Contact the Classification Society for calculation and approval in absence of such information.

- Any fixed or portable securing devices provided by the company or the charterer should be type approved by a Classification Society with relevant certificates.

- Do not weld securing devices to non strength structures and hot work should be carried out with Class approval.

- The installation, materials, tests and verification of newly added fixed devices should comply with the requirements of the Administration and the Classification Society.

- The ship should be supplied with sufficient lashing and locking devices in case any damages during the voyage.

- A fumigation certificate of the timber shoring should be available in compliance with the quarantine requirements at the port of discharge.

- Apart from the light over heavy principle, consider the ship’s stability when arranging stowage locations and the negative impact on ship equipment, cargo stowage and personnel safety based on the transverse force may arise during the voyage. Maintain the stability through adjustment of the stowage pattern or through ballast operation where necessary.

- Should any dangerous goods or reefers be loaded into the containers, the master should check whether a certificate for carriage of dangerous goods is available or whether the power supply is in compliance, or the unit should not be accepted for shipment.

- The crews should check and clear all devices in the holds after the discharge of containers so that subsequent loading of bulk cargoes won’t be affected.

- The maritime law in China has made different provisions with international transportation codes on whether empty containers can be defined as cargoes, and owners should refer to specific contracts for more information.

For more information, please contact Managers of the Association.